What Is a Well Pressure Switch and How Does It Work?

The beating heart of a well water system is a well pressure switch. When it malfunctions, the system’s other parts won’t perform at their highest level of efficiency and smooth water flow won’t be possible. Understanding the functions of a well pressure switch will assist you in maintaining the quality of your water, identifying problems with your appliances, and extending the life of your well water system. You can learn more about pressure switches below, including what they are, how they operate, how to recognise when one is failing, and how to fix the issue.

What is a well pressure switch?

Based on the water pressure inside a well water system, a well pressure switch is a device that switches a well pump on or off. Each well pressure switch has a cut-on and cut-off pressure that governs when the switch turns the pump on and off, unlike high pressure switches and low pressure switches used in HVAC applications. A well pressure switch controls how full or empty a well pressure tank is. A pump would need to run each time a tap or other fixture in a residence was opened in the absence of a pressure switch. Well pumps are not designed to work quickly or continuously, therefore this continuous on and off would significantly reduce the life of the pump.

How does a well pressure switch work?

When the system’s pressure falls to the cut-on point, a well pressure switch activates a well pump, which is turned off when the system’s pressure rises to the cut-off point. Common pressure limits in a well system include between 40 and 60 psi, between 30 and 50 psi, and between 20 and 40 psi. The air in the pressure tank expands as the pump is shut off and water starts to flow into a house, which causes the pressure to drop. The well pump activates and starts filling the tank as soon as the pressure reaches the cut-on point. The air inside the tank contracts when water is added, raising the pressure. The switch shuts off the pump once the pressure reaches the cut-off point until there is adequate water.

Types of well pressure switches

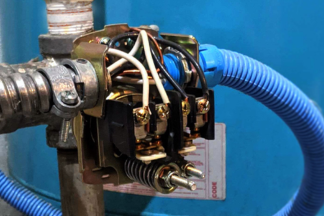

Well pressure switches come in mechanical and electrical varieties. The method by which the pressure applied to the inside of the switch is used to operate the switch is the major distinction between these two varieties of switches.

Electrical pressure switches can read pressure without direct contact, but mechanical pressure switches need physical contact to generate a signal. Mechanical switches provide an electrical switching signal without requiring an electrical source, but electrical pressure switches must always have access to power. Mechanical switches have factory-set cut-on and cut-off points that can be adjusted with a pressure-adjusting nut as opposed to electrical switches, which have programmable cut-on and cut-off points via buttons on the switch itself. Although a well can utilise any sort of pressure switch, mechanical switches are less reliable.

Common well pressure switch problems

You will notice it inside your home if a pressure switch stops functioning properly. However, the signs of a malfunctioning well pressure switch frequently point to a problem with another component of your well water system. A yearly inspection of your system might help you avoid many issues. You can save money, time, and the stress associated with replacements and repairs by diagnosing issues before they have an obvious impact on the water in your home.

Faulty well pressure switch symptoms

Common symptoms of a failing well pressure switch include the following:

Water pressure inside the home above the pressure switch’s cut-off point

Low water pressure inside the home

Pump turns on and off repeatedly

Pump does not turn on at all

Pressure tank is waterlogged

No water flow at all inside the home

All of these symptoms could indicate that your pressure switch is malfunctioning, but they could also point to an issue with another component of your system. For instance, a pump may not operate because the pressure switch is not sending a signal or because the pump’s parts are damaged. As a result, it’s crucial to get your equipment inspected by a specialist in order to identify any issues with your system. Causes and treatments for typical well-system symptoms are listed below.

How to test a pressure switch on a well

When a symptom of a bad pressure switch becomes evident, check that the power to the well has not been turned off before trying anything else. The well switch will be located near the pressure tank. If the switch was already on, check the breaker to ensure it did not trip. A breaker that trips regularly is a sign of a faulty well pump. Once you know that power is running to your well system, you can test the pressure switch.

To test a well pressure switch, follow these steps:

Turn the power off to your well system. Testing your well’s system with the power turned on can lead to electrocution.

Remove the switch’s cover. This may require a few screws to be undone.

Check if water is leaking out of the switch. If so, tighten it and observe if the leaking stops.

Check the switch’s contacts. If any of the contacts are damaged, the switch needs to be replaced. If not, clean the contacts until you can see the shine of the metal.

Ensure that the wires inside the switch are secure.

Check that the pressure adjustment nut is tightened to the correct pressure.

Once these steps are complete, restore power to your system and test if the pump turns on and off at the appropriate intervals.

Common well pressure switch problem solutions

Some well pressure switch issues call for a complete switch replacement, while others could only call for a portion of the switch to be changed. Even while other well system issues could appear to be the pressure switch’s fault, the switch itself is not to blame.

No water flow from pump

If there is no water flowing from your pump and, as a result, no water flowing in your home, the pressure switch may be to blame. The most likely pressure switch issues in this instance are worn-down contacts or a loose spring. These prevent the switch from activating the pump when the pressure reaches the cut-on point. If the electrical contacts are worn down, the entire switch must be replaced. A loose spring, on the other hand, can be switched out without needing the entire unit replaced.

If you have ruled out any problems with your switch and there is still no water flow, other devices may be the culprit.

Low water table: During a drought, the water table in your well may be too low for your system to access.

Power loss: A common cause of well system issues is a lack of power caused by a power outage or power surge. Ensure that the circuit is turned on.

Clogged filter: Sediment can infiltrate the water system and lead your filtration systems to become clogged. You can temporarily bypass your filters to ensure that this is the issue. Do not use the bypassed water for any purpose as it can be full of contaminants.

If your pressure switch won’t turn on or off, it might seriously affect your well system and property. The pressure tank will fill up too much and produce an excessive amount of water pressure if a pump does not shut off. The tank will overflow and get saturated, which will cause a sharp decrease in the water pressure within your home. Your pump or pressure switch springs may be the cause of a pressure switch that won’t turn on and off. The cut-on or cut-off points might not be achieved if the pump does not function at the proper pressure. Similar to that, if your switch cannot precisely detect the pressure, it might not turn the pump on or off. Upon checking your pressure switch,notice the springs are worn down, you can simply replace them.

Hire a professional to check for problems with your well pump if you have checked your switch and everything appears to be in working order. Pressure switches are far simpler parts than well pumps, thus trying to inspect the pump without experience might be difficult and result in inadvertent pump damage or a wrong diagnosis of the issue.

Pump cycles repeatedly

Short cycling is the term for the quick on and off of a pump. Although it could appear that there is an issue with the pressure switch, the well pressure tank is most likely to blame. The pressure inside a pressure tank is no longer controlled if its bladder ruptures. In certain circumstances, the pressure switch can repeatedly turn on and off because it depends on the pressure inside the tank to be adjusted. It is necessary to repair a pressure tank with a ruptured bladder right away. The pressure switch and pump may both sustain immediate harm if repair is postponed and the system is left running.