Causes Low Water Pressure

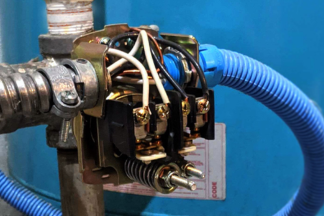

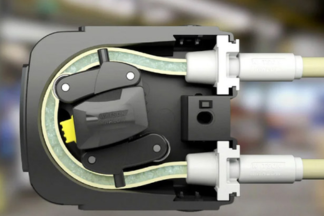

Low water pressure is an annoyance if you have ever battled to remove shampoo from your hair, washed your hands with a trickle of water, or had to wait for what seemed like an eternity for your washing machine to finish a cycle. Simple jobs can become complicated by low water pressure, but once you know what’s causing it, you can either address the plumbing issue or install a water booster pump to greatly increase your water pressure. The nine most typical reasons for low water pressure are discussed below, along with tips on how to raise the pressure in your home. Why is water pressure so low?Numerous problems, such as pipe corrosion, scale buildup, leaks, and even gravity, can result in low water pressure. The remedy: Regrettably, replacing your pipes is the only way to fix corroded pipes. Your water pressure should increase after the installation of new pipes. The best option is to replace your pipes when scale accumulation is severe enough to lower water pressure and restrict water flow. Scale can be reduced by products like CLR Calcium, Lime and Rust Remover, however when the scale is removed, it could clog your pipes and cause an additional expensive plumbing issue. Not to mention that putting harsh chemicals in the pipes that carry your drinking water is never a good idea. The fix: Find your main shut off valve, which is put in place where your home’s main water line enters, and fully open it by twisting it anticlockwise. Calling the local water provider to report low water pressure is the solution. Your feedback could help them identify the issue and guarantee that your water pressure is restored as soon as possible. Hire a qualified plumber to find the leak and fix it as a solution. Your water pressure should return to normal once the repairs are done. The solution: If your pressure regulator is currently set lower, raise it to 50 psi. Ask a plumber to replace your pressure regulator if it is malfunctioning. 7. GravityWater moves upward in opposition to the pull of gravity. The water pressure will be lower the higher the elevation from which the water must flow. Due to gravity, homes with numerous stories, apartment complexes, and skyscrapers may have low water pressure. Installing a water booster pump is the solution. Pumps for water pressure boosters both raise low water pressure and boost water flow. The fix: A water booster pump can raise water pressure and flow. The answer: Ensure that the water treatment equipment is sized correctly to prevent a significant pressure drop or flow loss. If necessary, add a booster pump to your water treatment system to increase water pressure. Just be careful not to position the pump in a way that forces water into the filters at a greater psi as this could harm the filtration system. Instead, position the pump so that it raises water pressure inside your house. How can you tell if your water pressure is low?The simplest approach to determine whether you have low water pressure in your home is to test the water with a pressure gauge. Once fitted, pressure gauges are easy to use, cheap, and allow you to quickly check your water pressure. Choose an outdoor tap close to where the main water line enters your home if the water you use comes from a municipal water source. Choose a tap that is close to the well’s pressure tank if your water comes from a well. Tighten the pressure gauge after attaching it to the tap. To get an accurate reading, make sure water isn’t being used anywhere else inside or outside the house, and then fully turn the faucet on. Now, you will be able to read the water pressure on the gauge’s dial. Typical home water pressure should be between 40 and 50 psi, so if the dial reads less than 40 psi, you have low water pressure. How to boost the pressure in your waterDepending on what is causing your water pressure to be low in the first place, you can determine the best way to raise it. If necessary, resolve the underlying plumbing issue, such as by replacing problematic pipes, resolving a leak, or repairing a broken pressure regulator. A water booster pump is a fantastic choice if your plumbing system is in good condition but you are not happy with your water pressure. A water booster pump is what?A centrifugal pump called a “water booster pump” can boost low water pressure and enhance water flow. A water booster pump’s rotating impeller takes water in and then forces it out with more force, similar to how fan blades produce air gusts, so increasing water pressure. Every tap and appliance will have better water pressure thanks to the installation of a water booster pump where the main water line enters your property. How to boost a well’s water pressureThere are three fundamental actions you can do to boost well water pressure: change the pressure switch on your tank, clean up your pipes, or construct a constant pressure system. Adjust the pressure switch on your tank Use a pressure gauge to check your water pressure. Adjust the pressure tank switch to increase your water pressure if the measurement is less than 40 psi. To adjust the pressure, find the pressure switch on the line that connects your well to your storage tank. Normal manufacturing settings for pressure switches include turning on the well pump when the pressure dips to 30 psi and turning it off when the pressure rises to 50 psi. The turn-off setting should be adjusted to a maximum of 60 psi. Additionally, maintaining your preferred water pressure and the effectiveness of a well system depend on having a pressure tank that is the right size. Inspect your pipes It is typical for minerals and silt to accumulate in a well system’s pipes, which can block the pipes, lower water pressure, and limit water flow. To restore low

Causes Low Water Pressure Read More »